Based on the important role of vascular network in delivering nutrition, oxygen and signal factors and real-time adjustment of tissue temperature and pH value, the construction of a three-dimensional network structure of blood vessels through tissue engineering will be important for the application and research of tissue repair, cell therapy and drug screening significance. In the application method of constructing vascular tissue engineering scaffold,3D bioprintingIt is possible to control the deposition of different biological functional components (such as seed cells, extracellular matrix and biological factors) in time and space.For example, the use of coaxial bioprinting bionic hollow fiber structure as a vascular catheter, but this construction method is difficult to prepare an internally connected vascular network; or use3D bioprintingDirectly construct a network structure rich in micropores and channels, but the ordered holes in the structure can easily lead to the instability of the network frame and the deformation of the bottom holes; or use sacrificial ink (sugar, PF127, etc.) in the pre-printed support A penetrating network structure is formed, but the printing method has low operating efficiency and has potential cytotoxicity to the loaded endothelial cells.

Recently, in order to overcome the shortcomings of the above method of constructing a three-dimensional vascular network, gelatin and GelMA are used as3D printingThe bio-ink, the Molly M. Stevens team at the Institute of Biomedical Engineering, Imperial College London, published an article titled “Void-Free 3D Bioprinting for In Situ Endothelialization and Microfluidic Perfusion” on Advanced functional materials, as shown in Figure 1A, The researchers used temperature-sensitive gelatin-based bio-ink as a printable sacrificial template, and photocrosslinkable GelMA as a template for filling the extracellular matrix. At 37°C, gelatin spontaneously dissolves to form a framework of penetrating blood vessel network.

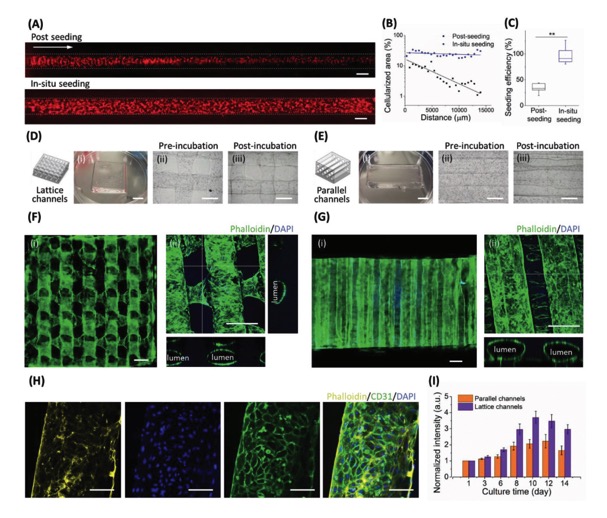

Using 7.5 wt% gelatin and 5 wt% GelMA as bio-inks, the researchers compared the direct3D printingMethod and no porosity3D printingMethod to construct GelMA gel network with pore structure.Achieve discovery of no porosity3D printingThe printability of the method is stronger, and the network structure of the gel is more stable.And this printing method is also suitable for other bio-inks3D printing, Such as double bond modified hyaluronic acid, etc. (Figure 2).

The researchers used human skin fibroblasts (HDF) and human umbilical vein endothelial cells (HUVECs) as cell models to explore the biologically active endothelialization process of the loaded cells in the gel scaffold. Researchers pre-loaded HUVECs into gelatin ink, directly printed out the non-porous structure and carried out subsequent culture. With the dissolution of gelatin, the adhesion and proliferation of endothelial cells, a three-dimensional and permeable endothelial structure can be obtained. In situ cell endothelialization experiments show that endothelial cells can be evenly distributed inside the pores, and can achieve good proliferation activity, forming a uniform connected network and parallel tubes. After 8 days of incubation, the high expression of endothelial cell adhesion marker CD31 in cell fluorescence staining indicated that HUVECs proliferated and formed a uniform cell monolayer (Figure 3).

In addition to the construction of vascular tissue engineering scaffolds, the researchers explored the non-porous3D printingWhether the method can be applied to the construction of hydrogel-based microfluidic chips. As shown in Figure 4, the researchers used PDMS as a scaffold to encapsulate and support the gel network.3D printingConstructed microfluidic chip models with different patterns. Experiments show that the microfluid can circulate uniformly in the gel network without diffusion. In situ endothelialization experiments based on the gel-based microfluidic chip show that endothelial cells can be evenly distributed in the inner cavity of the gel network and form a penetrating endothelial network structure.

In summary, the researcher passed the non-porous3D printingThe method realizes the construction of a personalized and uniform three-dimensional gel network with a tubular structure.Compared to other sacrificial inks3D printingIn this way, this method solves the problems of easy collapse of the three-dimensional gel network, difficulty in forming low-viscosity bio-inks, and low endothelial cell planting efficiency, and can be used to construct a hydrogel-based microfluidic chip with good internal intercommunication.

(Editor in charge: admin)

0 Comments for “AFM: Double nozzle extrusion 3D printing complex pore GelMA hydrogel for vascular model and microfluid perfusion culture”