China3D printingNet July 9th, with the steadily shortening of time to market in the automotive industry, the demand for additive manufacturing prototype components is higher than ever. However, according to a new study by the German multinational automobile company BMW, in order to make a larger 3D printing volume tangible, the process chain still needs to be optimized and further developed in terms of output, production speed and economic feasibility.

BMW determined that it needed to further optimize and improve the efficiency of additive manufacturing technology and its process chain, so it studied the complexity and economic value of artificial intelligence (AI) to automatically identify 3D printed parts.

The paper outlines the current status of the additive manufacturing process chain currently available, the complexity of using AI for part recognition, and the economic feasibility of using AI-based platforms such as AM-VISION, an automated machine learning part recognition system. AM-Flow, a Dutch 3D printing, post-processing and automation company, to further industrialize the entire 3D printing process chain.

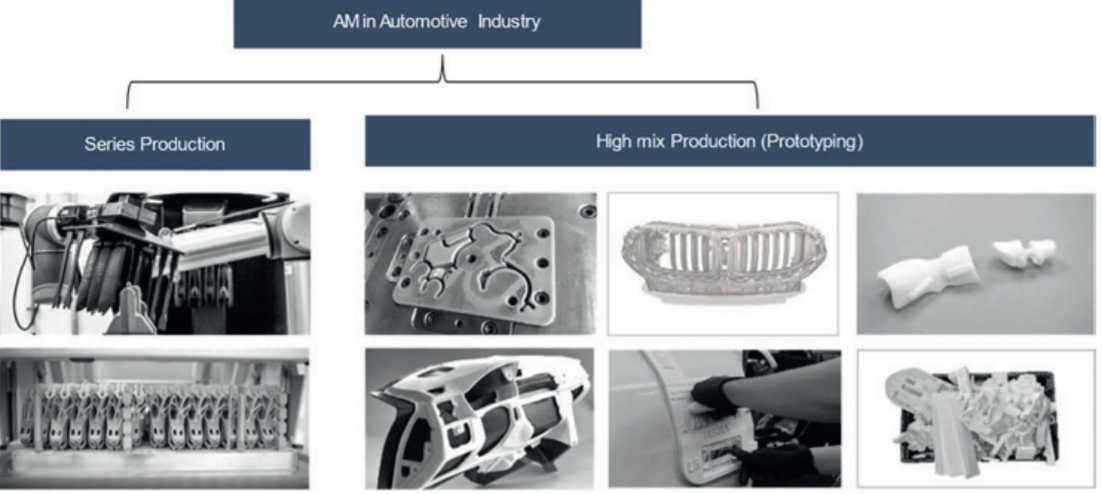

Separation of additive manufacturing components within the BMW Group. The picture comes from the BMW Group.

The additive manufacturing process chain in the automotive industry

This research paper, written by authors from BMW, AM-Flow and the University of Duisburg-Essen (UDE), focuses on how technological advancements in additive manufacturing can achieve higher production speeds, more material choices, and Robust mechanical properties of regulation. Parts similar to traditional products. Therefore, this technology is increasingly being adopted by industries such as automobiles to facilitate the testing and verification of new use cases in the field of vehicle components.

Researchers say that the greater geometric freedom brought by 3D printing makes it possible to produce new structures, shapes, and highly personalized and personalized components. Researchers say that the possibility of mass production is emerging, and it is available to the assembly line in time. .

However, they found that the additive manufacturing process chain still needs to be further optimized and developed to increase output, production speed, and economically feasible.According to research, many currently available3D printingThe technological process chain still includes a large number of labor-intensive tasks and steps, resulting in high personnel costs and low product yields. This can also lead to bottlenecks and downtime in the entire process chain.

Researchers have observed that in order to solve these problems, the additive manufacturing industry is shifting to automation and industrialization, as evidenced by new technologies, application patents, cross-industry partnerships, and government-funded projects. They also pointed out that the entire additive manufacturing automation market is expected to grow by 23% in the next ten years, reaching a potential revenue of $15 billion.

The use of HP MJF technology simplifies the entire AM process chain and has an operation duration percentage (AM-Flow time measurement) for manual component identification. The picture comes from Philip Obst.

Overcoming productivity constraints with AI

According to the authors, the current additive manufacturing process chain has reached the productivity limit of mass production due to machine capacity, running time and post-processing steps, as well as manual operations such as machine cleaning, preparation and uploading. One of these manual operations specifically identified by the researchers is to identify components by marking them and assign them to customers for further logistics transportation.

Although part identification is a small part of the entire process chain, compared with other steps (such as cooling), it is still an unscalable process step and requires a lot of manual work. Taking HP’s Multi Jet Fusion (MJF) technology as an example, researchers have observed that in order to achieve the lowest unit cost, components are usually closely nested with the support of professional software. This can result in a large number of batches of different parts in a build job, which means that the traceability of individual components may be lost, and the distribution of customer orders needs to be completed after production, which is usually a manual step.

There are currently several methods that can automatically identify components based on geometric shapes, such as weighing, point cloud scanning, image recognition, and computer tomography. However, each of these technologies has its shortcomings in terms of accuracy and cost. However, the researchers said that due to the development of deep learning algorithms that mimic human strategic thinking, innovations in the field of artificial intelligence have made the necessary combination of flexibility and automation possible.For some time, artificial intelligence has been used in the field of 3D printing for component screening, generating complex designs, and monitoring quality control. Nevertheless, the researchers said that so far, there is no automated solution on the market that can solve the complexity of identifying automated components of different geometric shapes.

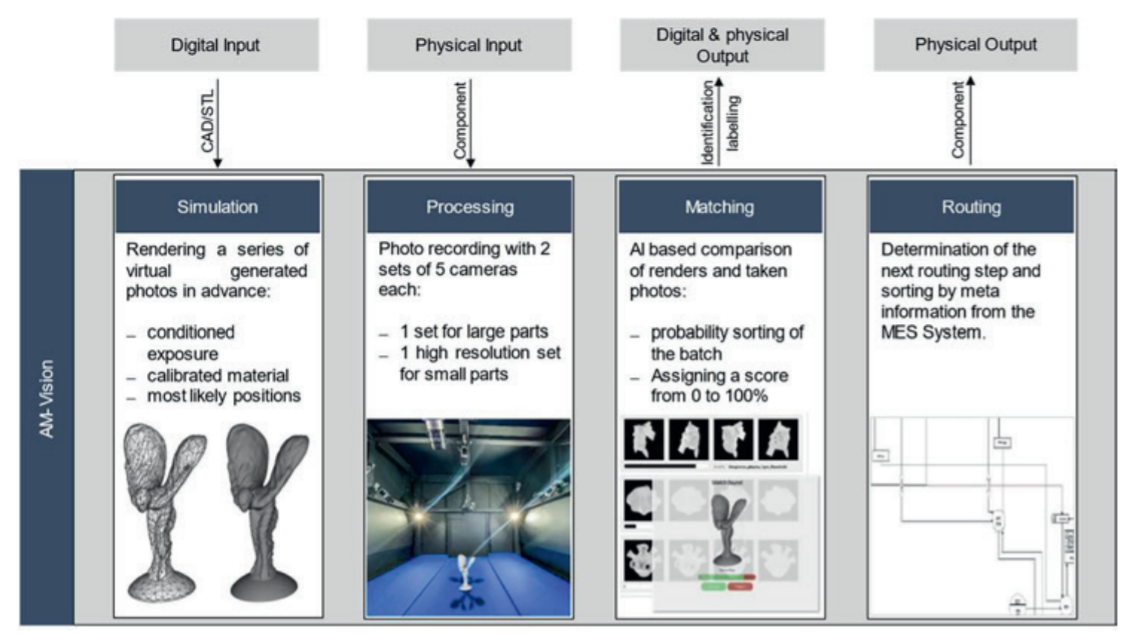

The functional principle and procedure of AM-VISION. The picture comes from Philip Obst.

Evaluate AM-VISION to identify AM components

AM-VISION is an industrial system used to identify additively manufactured components based on their unique geometry. The system was developed by AM-Flow, one of the winners of the Formnext 2020 Entrepreneurship Challenge, and the company’s flagship product for 3D printing and post-processing software products.AM-VISION uses 3D shape recognition technology to quickly and reliably recognize 3D printed parts based on geometric shapes. Once these parts are identified, they can be sorted, processed, picked and transported through the company’s other software programs AM-SORT, AM-PICK and AM-ROUTE. In October, the company raised US$4 million in Series A financing to build its AI-based robotics solution suite and promote the “phased change” of 3D printing automation.

Researchers conducted a series of evaluations of the AM-VISION system and investigated the economic feasibility of the software. Test research on construction tasks involving highly geometric combinations has proven that the system saves time in the identification and marking process, and the processing speed of the components is increased by 50% compared to manual operations.

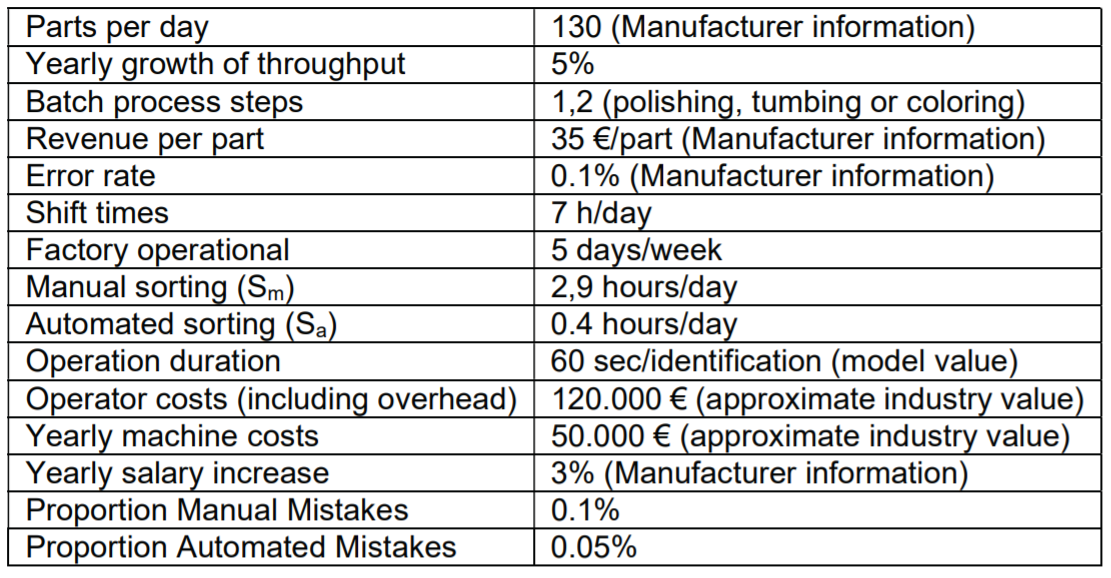

Used to compare input values for manual and automatic component recognition. The picture comes from Philip Obst.

By combining the final machine setup on the production line with an automated one-way conveyor, AM-Flow estimates that processing time can be shortened by 6 to 10 times, while the component recognition rate is 80% to 95%. The construction job contains highly diverse geometric shapes.

However, research on panels with finely embossed and engraved patterns on only one surface shows that artificial intelligence is not enough to distinguish on this scale. Therefore, the researchers suggest that the business case for artificial intelligence-driven 3D printed parts recognition depends on factors such as parts produced per day, failure costs, full-time equivalents, and labor costs to calculate the cost comparison with manual operations.

AM-Flow’s hardware solutions are designed to extend post-production processing. The photo is from AM-Flow.

The future industrialization of the additive manufacturing process chain

From their research, the researchers observed that although the production process itself is usually digital and automated, it requires a “high percentage” of manual work in the post-processing stage. They also emphasized that new developments and improvements in increasing the number of outputs have led to greater efforts in component identification, and that so far the deployment of artificial intelligence in this field has been effective.

Studies have confirmed that AM-Flow’s AM-VISION system can perform reliable object detection on highly mixed additive manufacturing components based on the partial representation of part geometry, thereby reducing production time and saving subsequent costs. Having said this, the author emphasizes the importance of choosing the correct application area for automatic identification, because the same parts, only slightly different parts, and parts that are too small to manufacture are not economically feasible for this technology.During the testing process, the deep learning algorithm of the AM-VISION system has been continuously improved, which helps to distinguish automotive parts with the rear-view mirror inverted. The researchers suggest that, looking forward to the future, using point clouds to measure dimensional accuracy can help achieve automated quality control, as can laser triangulation. With these additions, they believe that 3D printed series components can be identified by fine patterns, serial numbers, or small data matrix codes encoded into geometric structures.

The researchers concluded: “The currently available AM-VISION automatically recognizes a large number of high-mixtures is a further step towards large-scale AM production.”

China3D printingNet compile article!

(Editor in charge: admin)

0 Comments for “BMW Research Explores the Value of Artificial Intelligence in Automated AM Parts Recognition in Cars”