LEHVOSS

The Group is an industry-leading supplier of high-quality industrial thermoplastic materials. MaketBot, a Stratasys brand, introduces three new LUVOCOM® 3F materials from the group, aiming to expand its METHOD® 3D printingPlatform’s portfolio of advanced engineered materials.

This introduction brings the number of METHOD materials to 30, providing customers with a richer selection of production-grade materials.

- LUVOCOM 3F PAHT 9825NT

- LUVOCOM 3F PAHT CF 9891 BK

- LUVOCOM 3F PET CF 9780 BK

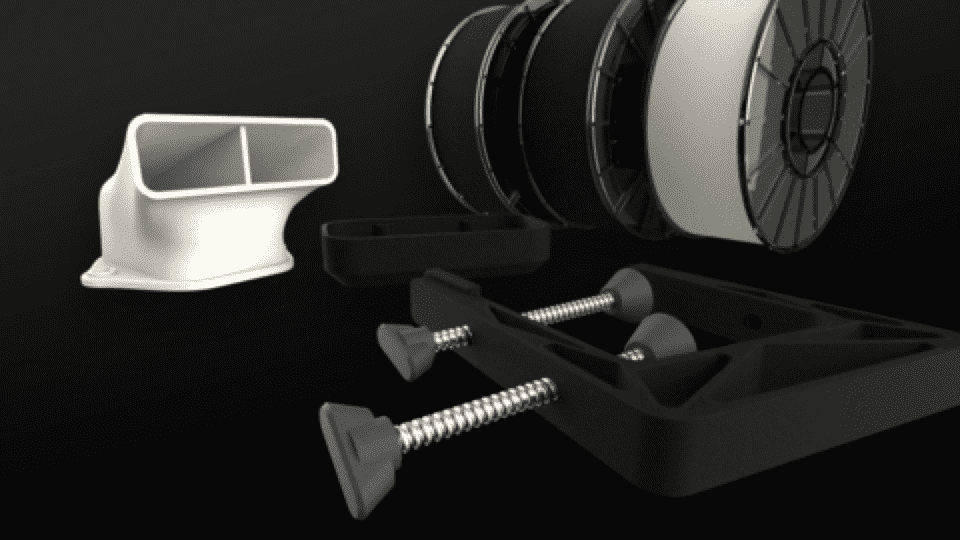

The above materials can be applied to METHOD and METHOD X through the MakerBot LABS second-generation experimental extruder. The LABS extruder transforms METHOD into an open platform for printing advanced engineered materials from leading filament suppliers.

LUVOCOM 3F series materials are designed for3D printingDesigned for industrial grade applications, it has similar performance to the compound version for injection molding. These materials are specially optimized for ease of printing with better performance and quality. Parts printed with these materials are strong, stiff, and have smooth surfaces, making them ideal for prototyping, jigs and fixtures, and end-use applications.

The MakerBot METHOD and METHOD X printers feature a unique heated chamber that allows semi-crystalline materials to be fully

post-processing

. Their outstanding performance in precision and repeatability, combined with our high-performance LUVOCOM 3F series of materials, provides customers with exceptional engineering performance.

—— Thiago Medeiros Araujo, Global Product Manager LUVOCOM 3F, LEHVOSS Group

We are always evaluating new materials to meet the needs of our customers and their applications. The METHOD platform’s additional ability to print more high-performance materials opens up more opportunities for users who want to test the advanced mechanical and thermal properties of different materials. The LEHVOSS Group, experts in engineered materials, brings a range of high-performance polymers to METHOD, allowing our customers to explore new and more challenging applications.

– Johan-Till Broer, VP of Product Development at MakerBot

LUVOCOM 3F series materials include:

LUVOCOM 3F PAHT 9825NT:

A high temperature resistant polyamide (also known as nylon) material, the continuous use temperature can reach 100 ℃, and the strength can reach PA/nylon 6. Compared with PA6, the material has 50% less water absorption and 4 times lower absorption rate. Lower hygroscopicity helps reduce printing problems and performance variations in printed parts. This material is optimized for low warpage, high strength, high impact resistance, and high surface finish for printed end parts such as flanges and fixtures.

LUVOCOM 3F PAHT CF 9891 BK:

The carbon fiber (CF) filled grade of LUVOCOM 3F PAHT 9825 NT has lower water absorption and better corrosion resistance to chemicals such as automotive fluids. The addition of carbon fiber strengthens its thermal and mechanical properties, and it can maintain 50% of its mechanical properties when it is used continuously at a temperature of 150 °C.The material is suitable for high temperature environments such as

car

Engine-related applications such as housings or hoods. In addition to its excellent mechanical properties, it is easy to print and less prone to warping.

LUVOCOM 3F PET CF 9780 BK:

It is a carbon fiber filled polyethylene terephthalate (PET) material that is easy to print, has low warpage, allows direct printing with excellent surface finish, and reduces the need for post-processing. The material has high strength, high temperature resistance up to 120 ℃, and chemical resistance is better than PETG.

As the only one in its price range that has a heated chamber and can print composites, polymers and metals in one piece3D printerMETHOD brings a unique 3D printing experience to users.

Its heated chamber controls the 3D printing process, allowing each layer to cool simultaneously to reduce warping and curling compared to other traditional tabletops3D printerParts can be printed more successfully with advanced materials.

(responsible editor: admin)

0 Comments for “MakerBot Introduces New Composite Materials from LEHVOSS Group, Strengthens METHOD Material Portfolio”