China3D printingNet September 23 news, for3D printingFood, I really need to stop thinking, “Okay, now I have seen everything!” Every time I do this, I will be proven wrong.The latest innovation comes from a team of researchers from the Singapore University of Technology and Design (SUTD) who successfully carried out3D printingMilk, yes, you read it right. I am not saying that you should get some biscuits and put the glass under the extruder.The team determined how to turn milk powder intoMilk food.

The university’s recently published a study in RSC Advances, investigating their method of changing the rheological properties of materials in order to use direct ink at room temperature3D printingMilk products.

3D printing

of” alt=” This edible sofa is made of milk powder

3D printing

“Width=”620″ height=”270” />

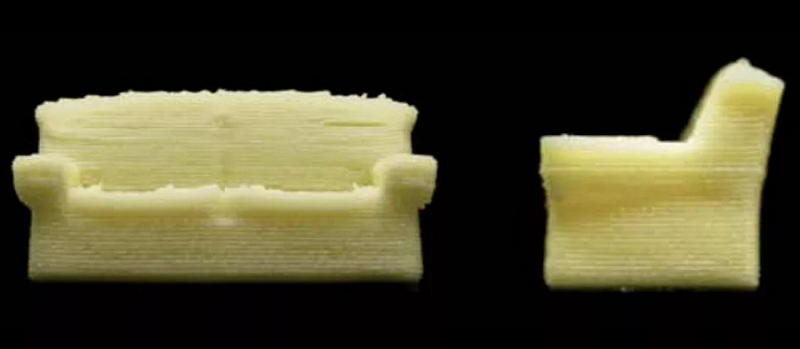

This edible sofa is made of milk powder3D printingof.

The summary states: “Food3D printingIt has been demonstrated through different methods, such as selective laser sintering (SLS) and hot melt extrusion. However, methods that require high temperatures are not suitable for creating 3D models composed of temperature-sensitive nutrients. Milk is an example of this type of food, which is rich in nutrients such as temperature-sensitive calcium and protein.Cold extrusion is3D printingAnother method, but it requires the addition of rheology modifiers and optimization of multiple components. In order to solve this limitation, we demonstrated the DIW of milk by cold extrusion with a simple formula of milk ink 3D printing. Our method relies on only one milk product (powdered milk). “

3D printing

For cold extrusion settings” alt=” For direct ink writing (DIW)

3D printing

For cold extrusion settings” width=”620″ height=”192″ />

For direct ink writing (DIW)3D printingFor cold extrusion settings. (A) A photo of the DIW printer used in the experiment. (B) DIW schematic diagram of a network structure on a glass substrate with emulsion ink.

Researchers want to avoid having to add most of the cold3D printingStabilizers required for the process, and printing milk that does not require high temperatures. In this case, additive manufacturing methods such as hot-melt extrusion and SLS will not work because they are generally incompatible with temperature-sensitive nutrients such as protein and calcium in many foods such as milk.

The lead researcher of the study, Assistant Professor Hashimoto explained: “Cold extrusion does not damage heat-sensitive nutrients, but3D printingIt can meet individual needs and has great potential in aesthetics and nutritionally controlled foods. “

Cold extrusion may be effective, but additives or rheology modifiers need to be added to increase the stability of the printed structure, which may be difficult to achieve. In addition, for DIW 3D printingThe ink needs to exhibit shear thinning behavior and have the ability to maintain shape after extrusion.

Therefore, the researchers studied how the concentration of milk powder affects the rheological properties of its milk ink, and then adjusted the performance accordingly to find the best solution. They completed an “extensive characterization” of the milk formula to analyze its rheology.

3D printing

Optical image of the milk model” alt=”DIW

3D printing

Optical image of the milk model” width=”620″ height=”235″ />

DIW 3D printingImage of the milk model of the milk. It can be clearly seen from the printing model that the concentration of milk affects the dispersion of printing ink. The mesh structure printed with M10, M60 and M65 inks spreads and fills the gaps. After printing with M70 and M75 (scale bar: 5 mm), the net structure of the printing is maintained.

They wrote in the paper: “Formula milk ink is based on a milk-based ingredient that controls its own ink rheological properties. By adjusting the concentration of milk powder, the rheological properties of milk ink can be changed, and its properties can be characterized and evaluated. Printability. Using inks containing 70-75 w/w% milk powder, we successfully printed complex 3D structures.” According to China3D printingNetwork understanding,Their formula contains only powdered milk, which is mixed with water to obtain it using DIW and cold extrusion methods3D printingThe correct consistency of the milk model. In fact, water is a factor that controls ink rheology, which makes the solution simple enough that it may soon be successfully used in a real-world scenario someday, such as in a nursing home or hospital, not just in a laboratory environment.

The lead author of the study, Li, said: “This novel and simple method can be used to formulate a variety of nutritious foods, including those that provide hospital patients with special dietary needs.” In order to determine the best printability, the researchers pass through3D printingClover leaves, cones, fortresses, wheels and small and cute sofas, tested their methods and materials, and made some other shapes. They also printed two-toned multi-material versions of the sofa by combining milk ink with chocolate made from chocolate syrup and cocoa powder, and tested how to fill the prints with materials such as cream, coconut and maple syrup.

SUTD teamuseVarious shapes are printed with 3D milk. A

0 Comments for “Researchers use cold extrusion technology to achieve 3D printing milk food”